What Is Cylindrical Brush Scrubbing and How Does it Work?

A cylindrical brush hard floor scrubbing machine will lay

down cleaning solution, scrub the floors with counter-rotating

brushes, then pick up cleaning solution at the same time with

the parabolic squeegee.

A cylindrical brush hard floor scrubbing machine will lay

down cleaning solution, scrub the floors with counter-rotating

brushes, then pick up cleaning solution at the same time with

the parabolic squeegee.

Cylindrical brush technology delivers low-moisture deep

scrubbing through concentrated brush speeds of 1300 RPM.

Designed for environmental sustainability, these units

conserve natural resources including water, solution and

source materials, and also operate at a whisper-quiet 67 dBa,

which is ideal for use in noise-sensitive environments such as

hospitals, nursing homes, schools, retail shops, restaurants,

airports, commercial buildings, and much more.

The Difference with Cylindrical Brushing

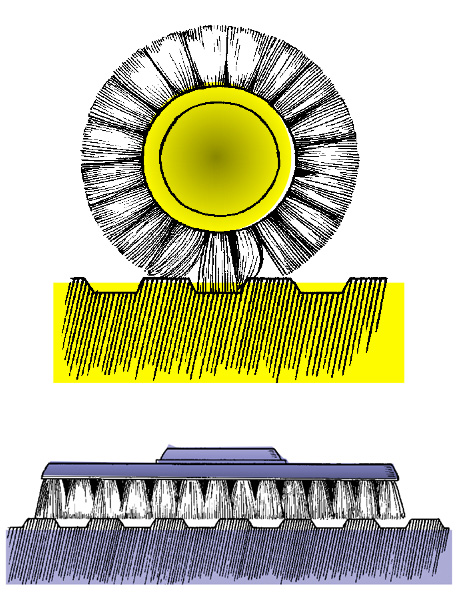

Simply put, with rotation speeds between 175 and 250 rpm, cylindrical brushing provides maximum hits to any surface. More hits means more efficiency, and with short bristles on every brush, cylindrical machines clean deep. For stone or grouted surfaces, cylindrical brushing is an easy way to get between every crevice. As well, the challenges of restroom cleaning can be minimized by the fast and high impact nature of this technique.

Simply put, with rotation speeds between 175 and 250 rpm, cylindrical brushing provides maximum hits to any surface. More hits means more efficiency, and with short bristles on every brush, cylindrical machines clean deep. For stone or grouted surfaces, cylindrical brushing is an easy way to get between every crevice. As well, the challenges of restroom cleaning can be minimized by the fast and high impact nature of this technique.

In particular, Tornado® cylindrical brush machines provide:

- 20 - 30% less water consumption

- 1000-1500 HIGHER RPM

-

- Over a dozen brush & pad combinations

- Zero splashing or over spray

- Counter rotation for agitation against tough surfaces

- Edge cleaning abilities

- Self cleaning brushes

- Greater contact pressure on uneven surfaces 6:1

Cleaning Uneven and Specialty Flooring with Cylindrical Brush Scrubbers

When challenged with cleaning uneven, porous or specialty hard floor surfaces there is really only one option — using cleaning equipment with cylindrical brush technology.

When challenged with cleaning uneven, porous or specialty hard floor surfaces there is really only one option — using cleaning equipment with cylindrical brush technology.

- 1. Increased Scrubbing Action

Tornado's cylindrical brush machines spin at between 650 and 1,500 rpm, depending upon the machine used. In contrast, discs floor machines generally only rotate at between 175 and 250 rpm.

- 2. Improved Contact Pressure

With cylindrical brushes, the downward pressure is concentrated within the inch and a half line of contact that the brush has with the floor. Increased concentration translates into higher pressure, with approximately six times that of a conventional disc unit. Increased pressure on the floor means better cleaning action.

- 3. Bristles vs. Pads

While disc pads ride over crevices and grout lines, cylindrical brushes reach in and clean them with ease. No other system works as well on cleaning grout and textured tile, period.

Cylindrical Brushing: A Key Component of Green Floor Care

The reduction of water and chemical use, sometimes referred to as low moisture floor care, is crucial to Green floor care.

Independent tests have found that cylindrical brush technology uses as much as thirty percent less water than conventional rotary machines, and this usually means that less chemical is used as well, reducing the impact cleaning has on the environment.

Cylindrical floor care equipment also addresses concerns regarding sustainability. The pads on rotary machines, which are usually constructed of nonrenewable resources, typically need to be replaced after each use simply. The brushes on cylindrical machines, on the other hand, typically equal 100 pads, creating less waste and having less of an impact on the environment.

Low moisture floor care is crucial to Green floor care. Independent tests have found that cylindrical brush technology reduces water consumption, and more importantly, reduces the use of harsh chemicals.

Cylindrical floor care equipment also addresses concerns regarding sustainability. The components used to manufacture them steer away from natural resources. Not to mention, their lifetime expectancy has increased 100 fold.

Real Customers. Real Examples.

“The BR Vario II cuts down cleaning time and labor,

thanks to the units ease of use and effectiveness

at penetrating tough-to-clean grout lines. With

the BR Vario II, we reduce scrubbing time by 50%

for each job. Being able to cut cleaning time in

half allows us to dramatically increase our profits

on each restoration and grout-cleaning project

we perform.”

Larry Kays, Operations Director

River City Building Maintenance, Richmond, VA

Saniglaze Franchisee

“To maintain Grinder’s standard of facility excellence,

we found that a traditional disc floor machine just

wasn’t able to penetrate our grouted tile. That’s when

we turned to the Tornado® BR 13/1 MW Compact

Scrubber with cylindrical brush technology to

address our hard floor cleaning challenges."

Brad Morgan, Vice President of Operations, Grinders Above & Beyond Restaurant, Ohio

“The less water used, the better. This also means less chemical is typically necessary, which decreases dry times and is more cost effective, efficient, and environmentally responsible.”

David Frank, President of the American Institute for Cleaning Sciences